- September 6, 2021

- Glass and Mirror Products Info

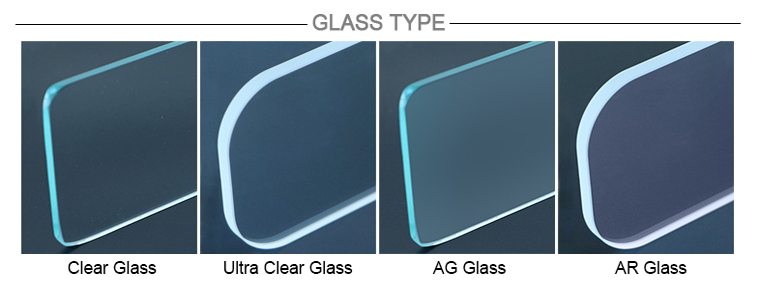

The Difference Between AR glass and AG glass

AR glass is anti-reflection and anti-reflection glass, which can increase light transmittance and reduce reflectivity.

AG glass is anti-glare glass, also known as non-reflective glass, the reflectivity is almost zero, can not increase the light transmittance.

Therefore, in terms of optical parameters:

AR glass has more functions to increase light transmittance than AG glass.

From the perspective of optical principles, AR glass is a film that can increase the transmittance and reduce the reflectance by adding a layer on the surface of the glass; while the AG glass changes the reflected light into diffuse reflection.

In terms of appearance, AR glass is smooth and transparent glass, and AG glass is glass with a little frosted effect on the surface.

AG glass is used in

1. PDP plasma TVs,

2. PTV rear projection

3.TVs, DLP TV splicing walls,

4. touch screens,

5. TV splicing walls,

6. Flat-screen TVs,

7. Rear projection TVs,

8. LCD industrial instruments and advanced picture frames.

AR glass is used in

1. Building curtain wall glass;

2. Various high-end exhibition halls and display windows;

3. Museum showcase glass;

4. Picture framing glass;

5. Solar photovoltaic glass;

6. Solar thermal glass;

7. Electronic information signage;

8. Airport tower glass;

9. Observation hall glass;

When to use AG glass and when to use AR glass

1.1 Transmittance: If the product requires more than 93% of the transmittance of the glass cover, AR glass is required. Float AG glass is generally 88%~91%.

1.2 Use environment: there is a strong light in the use environment of the product, or outdoors. We recommend the use of AG glass because AG processing makes the reflective surface of the glass become a matte diffuse reflective surface, which can make the reflective effect blur, and prevent glare, but also make the degree of reflection Drop, reduce light, and shadow.

1.3 Product cost: It depends on the market positioning of the product and the target customer group. There are also customers who use AG glass + AR coating to achieve product functions.

1.4 Tempered conditions: AR glass is basically tempered and then coated, and is basically surface treated in the state of the finished product. On the other hand, the surface treatment of AG glass is carried out in the original stage, and the shape is processed and then chemically strengthened and physically strengthened, and then surfaced Silkscreen.