- September 8, 2021

- Glass and Mirror Products Info

Eliterglass The Difference Between PVB vs SGP Laminated Glass

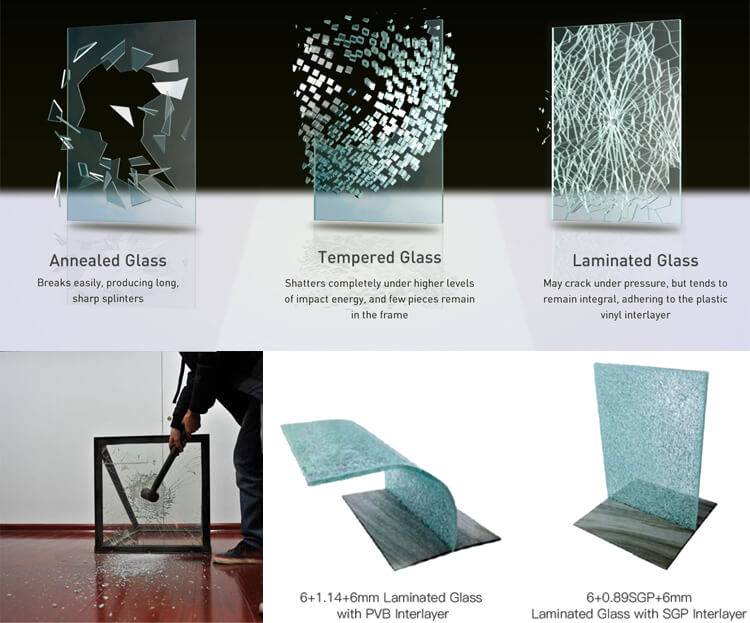

Laminated glass is basically a glass sandwich.

It is made of two or more plies of glass with a vinyl interlayer(EVA /PVB /SGP) between.

The glass will tend to stay together and case one in is broken – thus qualifying as a safety glazing material.

Here is the difference between PVB and SGP laminated glass:

Material:

SGP is an abbreviation of SentryGuard Plus Interlayer, crated by American brand Dupont.

PVB is Polyvinyl butyral, many brands all around the world.

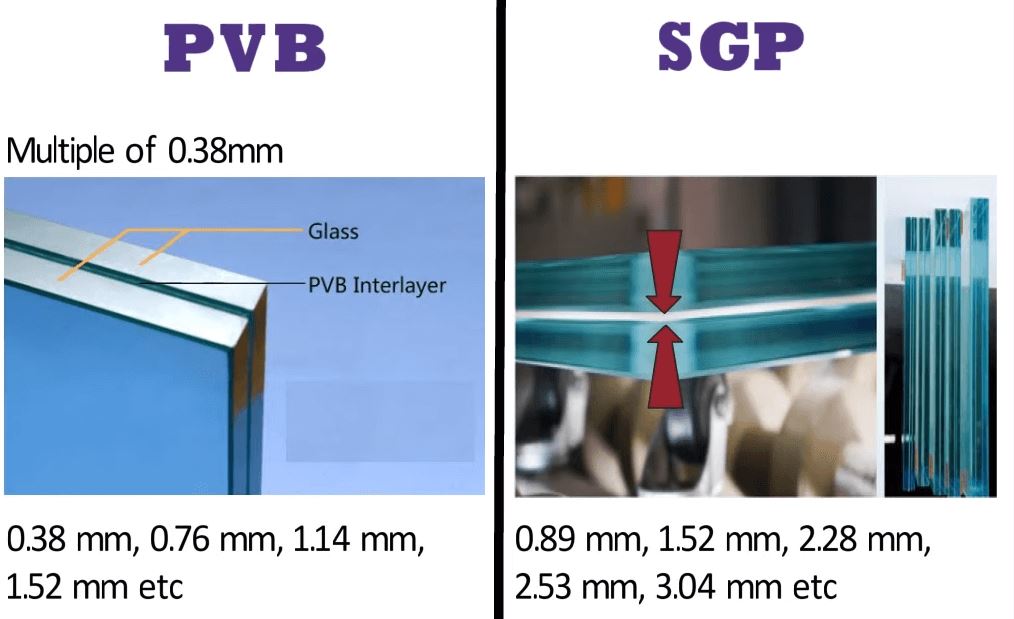

Thickness Difference:

The PVB film thickness is 0.38mm, 0.76mm, 1.14mm, multiple of 0.38mm.

The SGP film thickness is 0.89mm, 1.52mm, 2.28mm, etc.

Cost: SGP > PVB > EVA

Color Stype: EVA > PVB > SGP

( EVA film does well connected with many different materials, so it’s a very nice interlayer for decoration glass)

EVA has good fluidity of the film layer and can be subjected to a process such as wire drawing and engraving in the film layer to produce a

beautiful decorative glass with a pattern and a pattern. EVA has good water resistance.

Main Difference:

1. The main difference is “SGP” will stay standing when both sides are broken as compared to “PVB” which will fall down or break when both sides have become damaged.

2. Safety: The SGP laminated glass is five times stronger and up to 100 times stiffer than PVB laminated glass. That’s why designers like to use SGP laminated glass for applications that face bad weather like storms, hurricanes, and cyclones, also for someplace with war or that needs high security.

3. Clarity: The SGP yellow index is smaller than 1.5, while normally the PVB yellow index is 6-12, so the SGP laminated glass is much more clear than PVB laminated glass.

4. Cost: Since SGP is more expensive than PVB laminated glass if the environment or situation is not bad, PVB is more cost-effective than SGP laminated glass.

EVA‘s cost performance is higher. Compared with PVB and SGP, EVA has better fluidity, lower melting temperature, and can be processed at temperatures up to 110 °C.

Application:

1) PVB laminated glass: railing, fence, stair, floor, shower room, tabletop, windows, glass sliding door, glass partition, glass skylight, glass

curtain wall, windows, glass doors, glass facade, windshields, Bullet-proof glass, etc

2)SGP Laminated glass: Bullet-proof glass, Explosion-proof glass, High-speed train windshield, Railings -SGP hurricane glass, Ceiling, skylight, staircase, steps, floor, fence, canopy, partition, etc.

3)EVA: UV resistance is weak. It is easy to yellow and black in long-term sun exposure, Most used for indoor, partitions, decoration.