- October 7, 2021

- New Products

Eliterglass-China Factory TPS Insulating Glass Introduction

Due to its superior energy-saving performance, Low-E insulating glass has been used more and more widely in buildings.

And the insulating glass is filled with an inert gas such as argon.

More and more warm edge spacer is used to replace traditional aluminum spacer.

Here we introduce TPS insulating glass.

What’s TPS insulating glass?

TPS is short for THERMOPLASTICS PACER.

TPS is a new type of insulating glass warm-edge system, which uses special butyl rubber as auxiliary material and is filled with thermoplastic spacers of desiccant which Can perfectly replace traditional aluminum spacers.

Features of TPS Insulating Glass

(1) TPS thermoplastic spacers do not contain metal inserts, which improves the thermal barrier of the glass edge;

(2) Have a more even surface temperature distribution on the inner and outer glass surfaces effectively reducing condensation;

(3) Elastic edge sealing makes the glass design more flexible and convenient, which guarantees the IGU quality and stability.

(4) Automatic production, High-quality control, longer life;

(5) The secondary sealant can be silicone or polysulfide sealant.

Let’s Analysis the TPS Insulating Glass

1. Excellent thermal conductivity.

The edge sealing materials of insulating glass include an aluminum spacer, steel, and stainless steel materials, organic silicon materials, etc.

Due to the different thermal conductivity of the materials, the heat conduction formed at the glass edge is also very different.

The below table shows the thermal conductivity of different types of materials used in insulating glass.

The Edge Sealing Materials Compare

Thermoplastic spacers (TPS) abandon aluminum, stainless steel, and other metals with good heat transfer.

The linear thermal conductivity of insulating glass made of TPS is much lower than that of traditional products, which prevents heat loss at the glass edge. Thereby improving the energy-saving effect of the whole window.

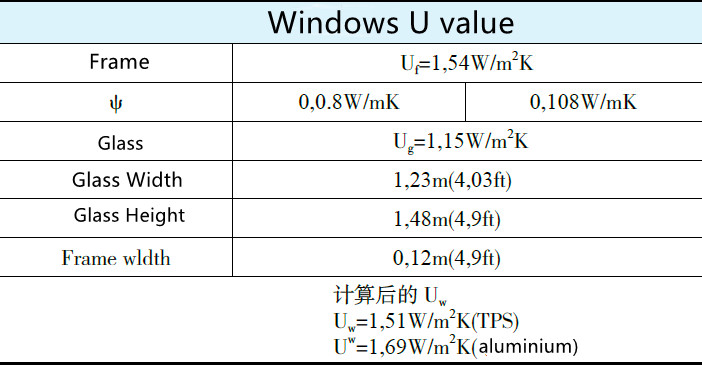

Windows U value Compare

TPS has better heat barrier properties than aluminum IGU.

It can significantly increase the air temperature near the window and reduce the indoor temperature difference.

It also has a stable indoor climate, lower air convection, a more comfortable indoor environment, and reduces condensation on the edge of the glass, reducing the maintenance cost of the window frame.

Indoor and Glass Surface Temperature Compare

2. Low Vapor &Air transmission rate

TPS is directly extruded with special butyl rubber mixed desiccant, and the consistency of the sealing material is good.

At the same time, because the TPS can also form an intimate chemical bond with secondary silicon sealant, the IGU structure is more stable

with higher bonding strength.

According to the GB11944-2012 test, the TPS IGU system has the lowest argon leakage rate, the test kept 5 cycles * 77days test, argon content

decreased by around 4% after 5 cycles weather simulation, lifetime is much better than current other insulating glass systems.

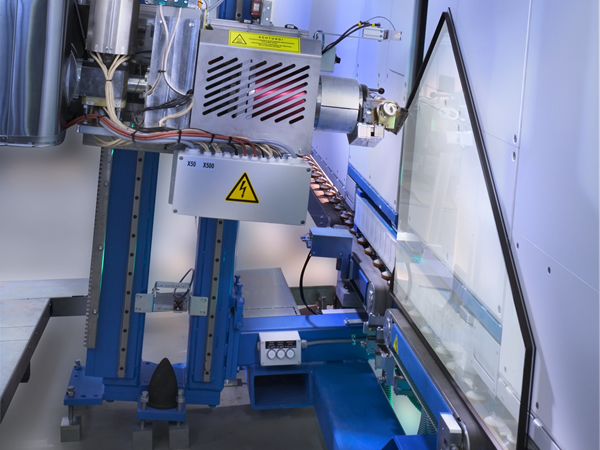

3. Automatic glass production.

TPS insulating glass system is produced by fully automatic machines.

From glass handle and loading, the removal of the glass edge coating, the cleaning and drying, the placing of the thermoplastic strip, the argon filling, and glass bonding, and secondary sealant are produced by an automated system.

Avoiding errors and inconsistencies that may be caused by manual operation, achieving a high degree of uniformity of corner sealing, completely eliminating the poor corner sealing of traditional aluminum insulating glass, and being suitable for producing TPS IGU in any type and size.

Shaped Insulated Glass Production with TPS

4. Perfect sealing performance, acoustic performance

The good mechanical properties and peel strength of TPS ensure the edge sealing performance under positive and negative pressure.

The elasticity of TPS thermoplastic spacers ensures that it can be applied to frequent changes in external temperature and wind pressure,

and has good anti-resonance and sound insulation properties.

With the increased requirement of passive houses and stricter energy-saving demand.

TPS will finally replace traditional aluminum ones, it will become the final element that can be upgraded in the IGU system.

Have the TPS insulating glass system in your project from China, just contact us.

Eliter Glass, is an excellent architectural and interior glass provider, manufacturer, and delivers glass to worldwide, and

professional solutions for building glass and decorative glass applications.